Understanding the Sleeve Part 2: The Sleeve Cap Curve and Ease

There are four parts to this article on Understanding the Sleeve and they follow on from each other.

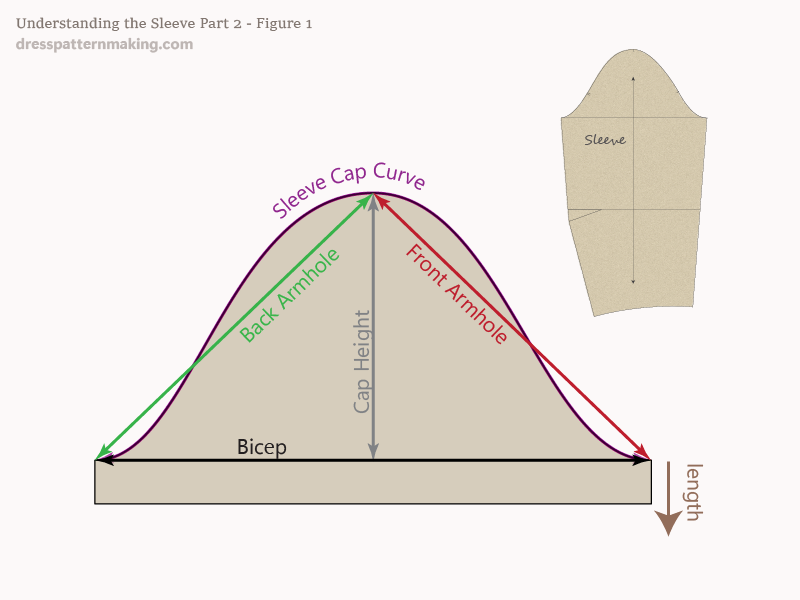

The main fitting problem with sleeves, or at least the difficult part to understand, is the armhole. Fitting as regards to the length of the sleeve is fairly straightforward and I don't think needs detailed explanation. Therefore, for these articles, the examples graphics I use are short sleeves, with a length of only 1 inch (2.5 cm) below the armhole. This makes the sleeve cap easier to see in the graphics. (The actual sleeve that is created in the Block Making instructions is a long sleeve with a dart in the elbow. A small version is shown in the first image in the top right-hand corner).

Okay, so we've covered what a Fitted Sleeve is, and you should be clear that we want (the ideal, anyway) is minimal ease in the bicep and minimal ease in the sleeve cap. So now, in the remaining parts of this article, we will look at how the sleeve is constructed, what measurements are used, and how we create a sleeve cap that has the right shape and minimal ease.

Parts of the Sleeve Cap

In the image below is the armhole part of the sleeve with its parts.

The Curve

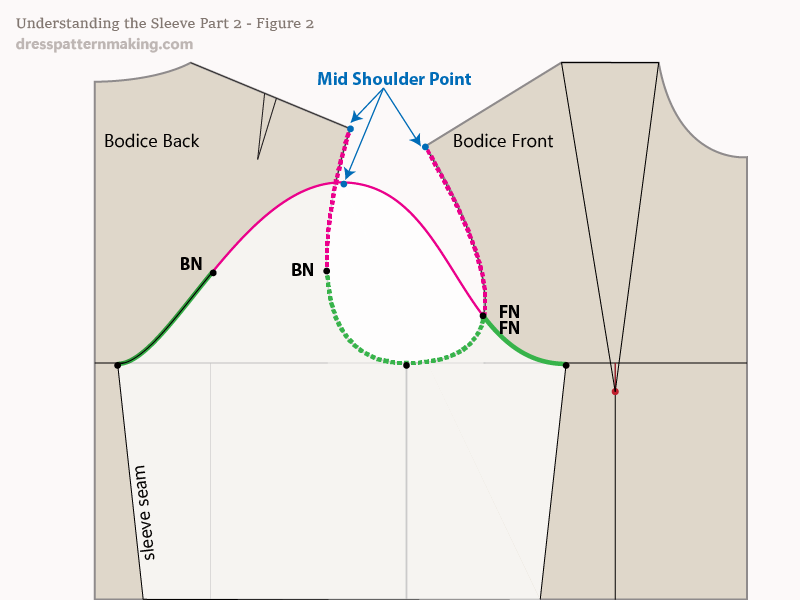

The curve is the shape it is so that it can be sewn into the round of the armhole. In the image below the sleeve is superimposed in white on the Bodice Front and Back and is a slightly transparent so that we can see both the armholes and the sleeve cap.

The pink part of the curve corresponds to the pink dashed lines of the upper part of the armhole on the bodice - front and back. The green lines on the curve are where the armhole turns inwards. You have to imagine the sleeve seams sewn up and you see the shape matches the armhole. There are usually notches that show where that turning point is - where the pink and green lines meet. Those notches are on both the Bodice Block and on the Sleeve Block, so they can be matched up. (BN for Back Notch and FN for Front Notch).

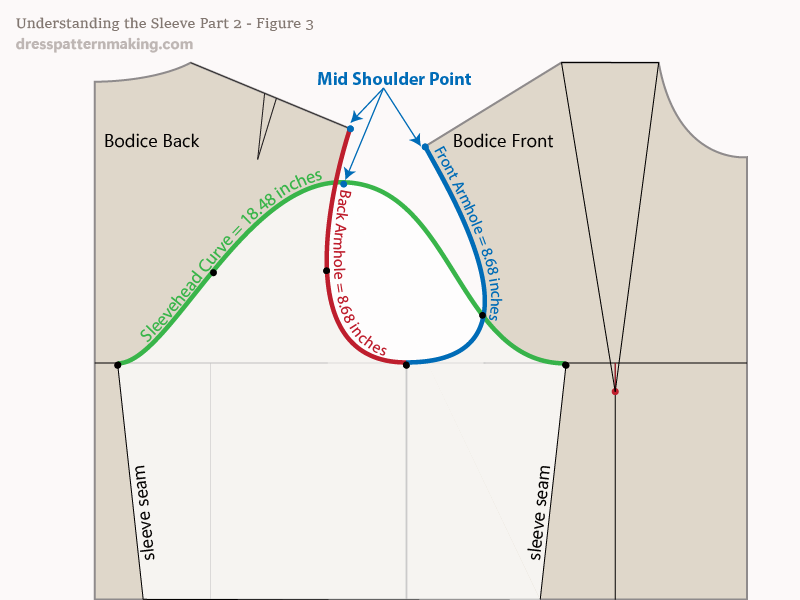

Ease in the Curve

In order to get the curve of the Fitted Sleeve into the round of the armhole, it has to have a certain amount of ease. This means the measurement of the curve needs to be greater than the measurements of the front and back armholes added together. If this ease wasn't added, you wouldn't be able to sew the pieces together. The standard amount of ease for a Fitted Sleeve, or a Fitted Sleeve Cap, is between 1.25 and 1.75 inches (3 and 4.5cm). This means that the total length of the Sleeve Cap curve has to be that much longer than the lengths of the front and back armholes added together. As in the image below: the difference between the armhole measurements added together and the sleeve cap curve is 1.11 inches, which is a bit less than the standard, but still enough. (Most patternmaking books say 1.25 - 1.75 inches is needed, but I have read in Fitting Books that just under 1 inch is preferable).

Additional Ease

I've said this before, but it bears repeating: You can have a lot more ease than this in the Sleeve Cap, which will result in gathers or pleats at the top of the sleeve. This is usually added when making a pattern, but the block that you use to make the pattern has only the minimum amount of ease. That is the general rule for patternmaking: the basic blocks have minimal ease, and you add fullness to a pattern created with the block.

Creating the Curve and Getting the Required Ease

The curve may seem complicated, but it's not that difficult to create. There is a triangle underneath that sleeve cap curve, and if you have the measurements of the triangle correct, creating the curve and getting the required amount of ease is quite simple. Below is an indication of this. Step-by-step details of how to create the curve can be found in the Video Instructions for Creating a Sleeve Block.

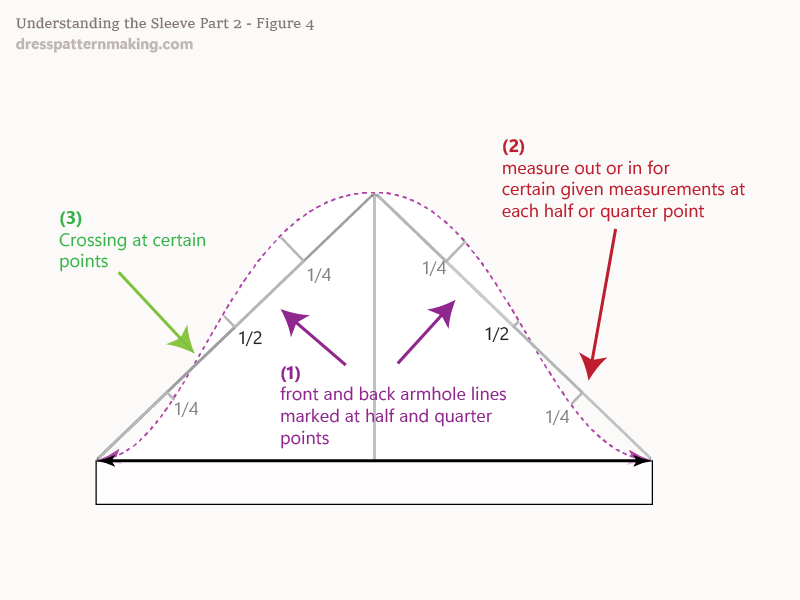

- The Front and Back Armhole lines are marked at half and quarter points.

- You measure in or out at those half/quarter points as specified (this varies quite a bit depending on the block instructions, see the final image on the page).

- You cross at given points, and

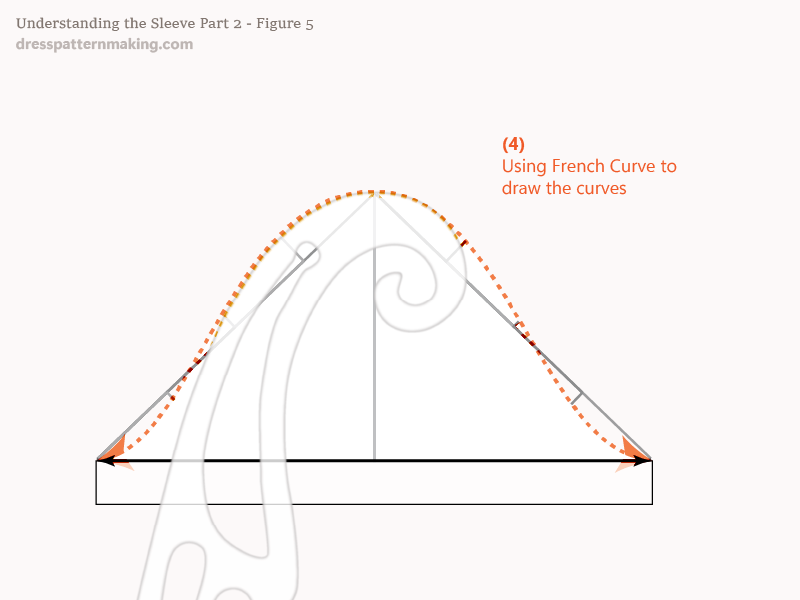

- Ue a French Curve to draw the curve (image below).

The Curve: Some Leeway

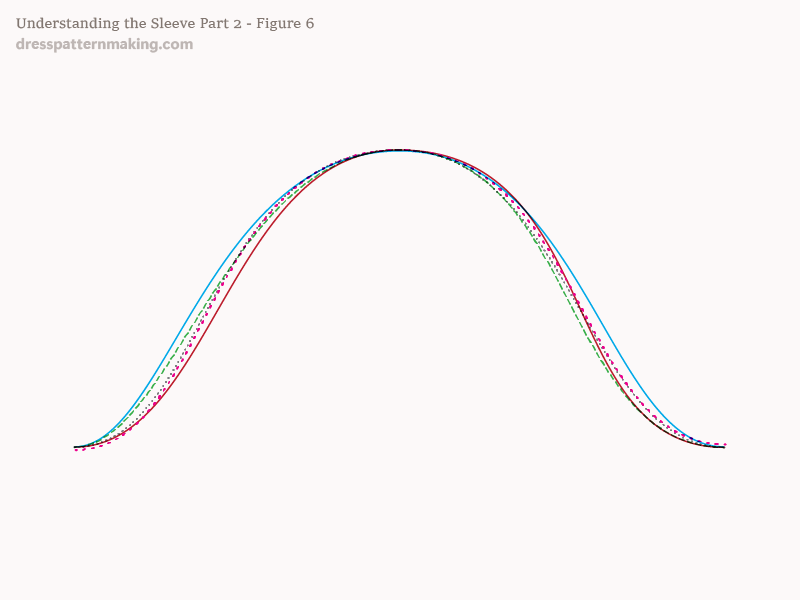

What's really important to know about the Curve is that it is not an exact science. There is a general sleeve shape that fits into the armhole, but different block making instructions will end up with a slightly different curve. Below are a number of different curves created for the same armhole and bicep measurements, using different block making instructions:

So.... when you creating the curve, you don't need to get it right to the nth degree. If you go out a fraction more or less than the instructions you are using, it's not going to make a big difference.

The Triangle underneath

What is really important to understand with the sleeve is the triangle that underpins the curve. The triangle that consists of the front and back armhole measurements, and the bicep. Understanding this triangle is essential to understanding the sleeve. See the next part of the article - Part 3: The Triangle.